RESPONSIBILITY

From design to distribution, we make every decision with people and the environment at the forefront. Our mission is to forge a path that allows the very traditional industry of artisanal footwear to think about new ways of working while sustaining our planet’s resources

A short production circuit, carefully selected suppliers and justified costs - these are our commitments that have remained constant since our inception. By controlling nearly 100% of our supply chain and incorporating zero-waste technologies, our approach is a celebration of modern innovation and family values, ensuring a greener legacy for generations to come.

THE DESIGN

At INGILIZ, we craft our shoes with your needs at the forefront of our creative process. Each pair is conceived and meticulously designed in our home design studio.

THE MATERIALS

We carefully select leather materials with minimum or zero impact on the environment. We use exclusively deadstock leather from renowned brands' tanneries in Italy and France and leather that is a bi-product from the food industry.

THE KNOW-HOW

Each pair is the epitome of our family heritage handed down through generations, where true craftsmanship and artisanal tradition is enhanced with cutting-edge technologies.

OUR LEATHER

We use exclusively deadstock leather from renowned brands' tanneries in Italy and France and leather that is a bi-product from the food industry. All materials are vegetable tanned. We only use LWG-certified suppliers. INGILIZ optimizes the use of leather, which has a direct impact on the generated waste and indirectly leads to a reduction in carbon emissions and will partially affect Scope 3.

OUR SHOE LASTS

We have our own department for designing and producing shoe lasts. As a result of our advanced technology, our shoe lasts are 100% zero-waste - any technological loss and amortized lasts are being recycled. The technology operates with 100% green electricity from INGILIZ's rooftop photovoltaic power plants.

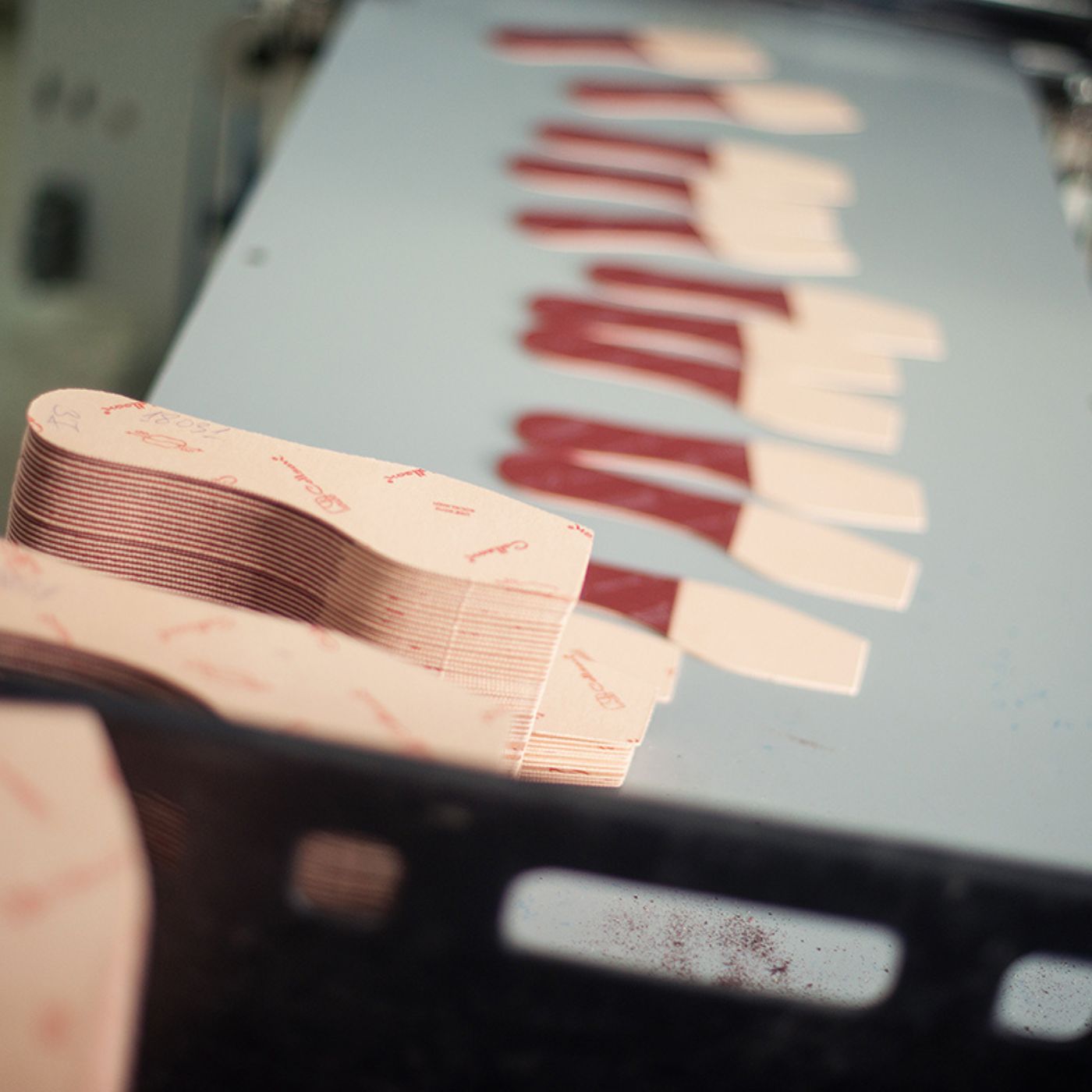

OUR INSOLES

We have our own department for designing and manufacturing shoe insoles. The manufacturing process utilizes recycled craft and FSC-certified materials and 100% green electricity from INGILIZ's rooftop photovoltaic power plants. All glues are water-based.

OUR SOLES

We have our own department for designing and manufacturing of natural craft soles. We use recycled skins – a bi-product from the food industry. All materials are vegetable tanned. We only use LWG-certified suppliers. The production process is powered by 100% green electricity from INGILIZ's rooftop photovoltaic power plants

OUR HEELS

Our heels are crafted from recycled ABS – a recycled plastic compound that is considered by industry experts more durable and easier to recycle after the shoe wears out. The zippers are made of recycled water bottles in all our products.

OUR PACKAGING

Each pair of INGILIZ shoes is wrapped in 100% recycled tissue paper and comes with a dust bag made of organic cotton. Your new pair of INGILIZ shoes is packed into a box made of recycled craft and FSC-certified materials.

4 in 1

4 own factories for control over the supply chain by building inhouse shoe components manufacturing facilities.

7

7 quality management and auditing systems that oversee process integrity and minimize environmental impact.

100%

100% handmade in our family-owned factory.